Warehouse Cleaning New Brighton, MN

(What actually works—and what fails—inside real warehouses)

If you manage or operate a warehouse in New Brighton, Minnesota, you already know this: warehouse cleaning isn’t about looking clean. It’s about keeping product moving, inspections quiet, employees safe, and equipment alive longer.

Most cleaning companies don’t understand that. They treat a warehouse like a big office. That’s how dust builds up on racks, floor grit chews up forklifts, and safety audits get uncomfortable.

Warehouse cleaning is a systems problem, not a cosmetic one.

What “Warehouse Cleaning” Really Means (Not the Marketing Version)

Warehouse cleaning means controlling dust, debris, oils, and buildup in environments where:

- Forklifts run all day

- Pallets scrape concrete

- Dock doors stay open

- Air moves constantly

- Inventory sits overhead

In facilities near Silver Lake Village, along Old Highway 8, or close to I-35W corridor, warehouses tend to deal with:

- Heavier dust loads

- Seasonal salt and moisture

- Mixed-use spaces (office + warehouse + dock)

A real warehouse cleaning plan accounts for all of that—by zone, not by checklist.

Where Warehouse Cleaning Fails (And Costs You Money)

Here’s where most facilities get burned:

Floors cleaned “sometimes”

Spot mopping doesn’t cut it. Grit embeds into concrete, traction drops, and forklifts wear faster. That’s a maintenance cost hiding as a cleaning problem.

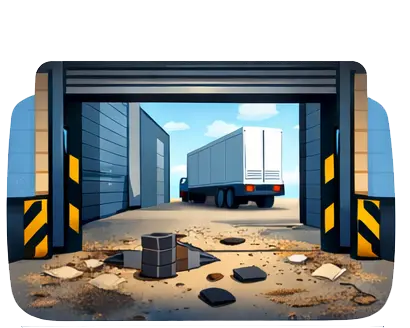

Dock doors treated like hallways

Loading areas take the hardest abuse. If they’re cleaned like offices, oil and debris build up fast.

Racks ignored

Overhead dust falls—onto product, packaging, and employees. This becomes a safety issue, not a cleanliness one.

Bathrooms and breakrooms underweighted

These spaces drive employee satisfaction and compliance—but they’re often rushed because crews are overwhelmed by floor time.

Warehouse cleaning has to prioritize risk first, not appearance.

How We Approach Factory Cleaning in New Brighton

Zone-Based Cleaning

Instead of “weekly cleaning,” we break facilities into:

Production / storage zones

Dock & loading zones

Traffic lanes

Employee spaces

Each zone gets a different frequency and method.

Schedule That Doesn’t Fight Operations

Cleaning happens:

After shifts

Before inspections

Around shipping windows

Not during peak movement.

Dust Control, Not Just Removal

In areas near Long Lake Regional Park and older industrial pockets, airborne dust is real. We focus on:

High dusting before it falls

Floor scrubbing that pulls grit out of concrete

Controlled dry methods where moisture causes problems

Who This Warehouse Cleaning Is Actually For

This works best for:

Distribution centers

Manufacturing warehouses

Storage facilities with active traffic

Mixed-use warehouse/office buildings

Facilities preparing for audits or inspections

If your building is near Northwest Passage or tucked into New Brighton’s industrial corridors, this approach fits your reality—not a generic template.

What You Gain When Warehouse Cleaning Is Done Right

Fewer slip and trip incidents

Longer floor and equipment life

Cleaner product handling areas

Easier audits and inspections

Less internal friction (“why does this area never get cleaned?”)

That’s operational stability—not aesthetics.

Why Local Experience in New Brighton Matters

Warehouse cleaning in New Brighton isn’t the same as downtown Minneapolis or rural storage facilities. Local factors matter:

Weather-driven debris

Industrial zoning layouts

Older concrete floors

Mixed-use buildings

A cleaner unfamiliar with this area will miss those details. That’s where problems start.

Warehouse Cleaning FAQ

What is warehouse cleaning?

Warehouse cleaning focuses on floors, racks, docks, dust control, and high-traffic zones to support safety, efficiency, and compliance—not just appearance.

How often should a warehouse be cleaned?

Most New Brighton warehouses need daily light maintenance, weekly detailed cleaning, and periodic deep floor scrubbing, depending on traffic and use.

Is warehouse cleaning different from janitorial cleaning?

Yes. Warehouse cleaning involves industrial floors, dust management, dock areas, and equipment-safe methods. Janitorial cleaning alone is not sufficient.

Does warehouse cleaning reduce safety risks?

Yes. Proper floor care, debris removal, and dust control significantly reduce slip hazards and overhead contamination.

Can warehouse cleaning be scheduled outside operating hours?

Absolutely. Most effective warehouse cleaning is done after shifts or during low-traffic windows.

If you’re searching for warehouse cleaning in New Brighton, MN, don’t judge providers by how clean the lobby looks.

Judge them by:

How they handle floors

How they manage dust

How well they understand warehouse flow

That’s where real value shows up.

Brown Janitorial Services LLC

NEW BRIGHTON

Business Hours

Monday - Friday : 8AM - 4PM

Saturday - Sunday : Close

Useful Links

© 2026 Brown Janitorial Services LLC | All Rights Reserved